Sustainable Innovation: Banana Fiber Sanitary Pad Making Machine

At GRIT Engineering, we believe true innovation solves real problems. This project showcases the design and fabrication of a semi-automatic sanitary pad manufacturing machine that uses banana fiber — a sustainable agricultural byproduct — as its primary absorbent material.

Redefining Menstrual Hygiene Sustainably

Conventional sanitary pads depend heavily on synthetic, non-biodegradable materials, contributing significantly to environmental waste. Our solution replaces these materials with banana fiber, a biodegradable, renewable, and cost-effective alternative.

By transforming agricultural residue into a valuable hygiene product, this innovation bridges the gap between sustainability, affordability, and women’s health.

Engineering the Solution

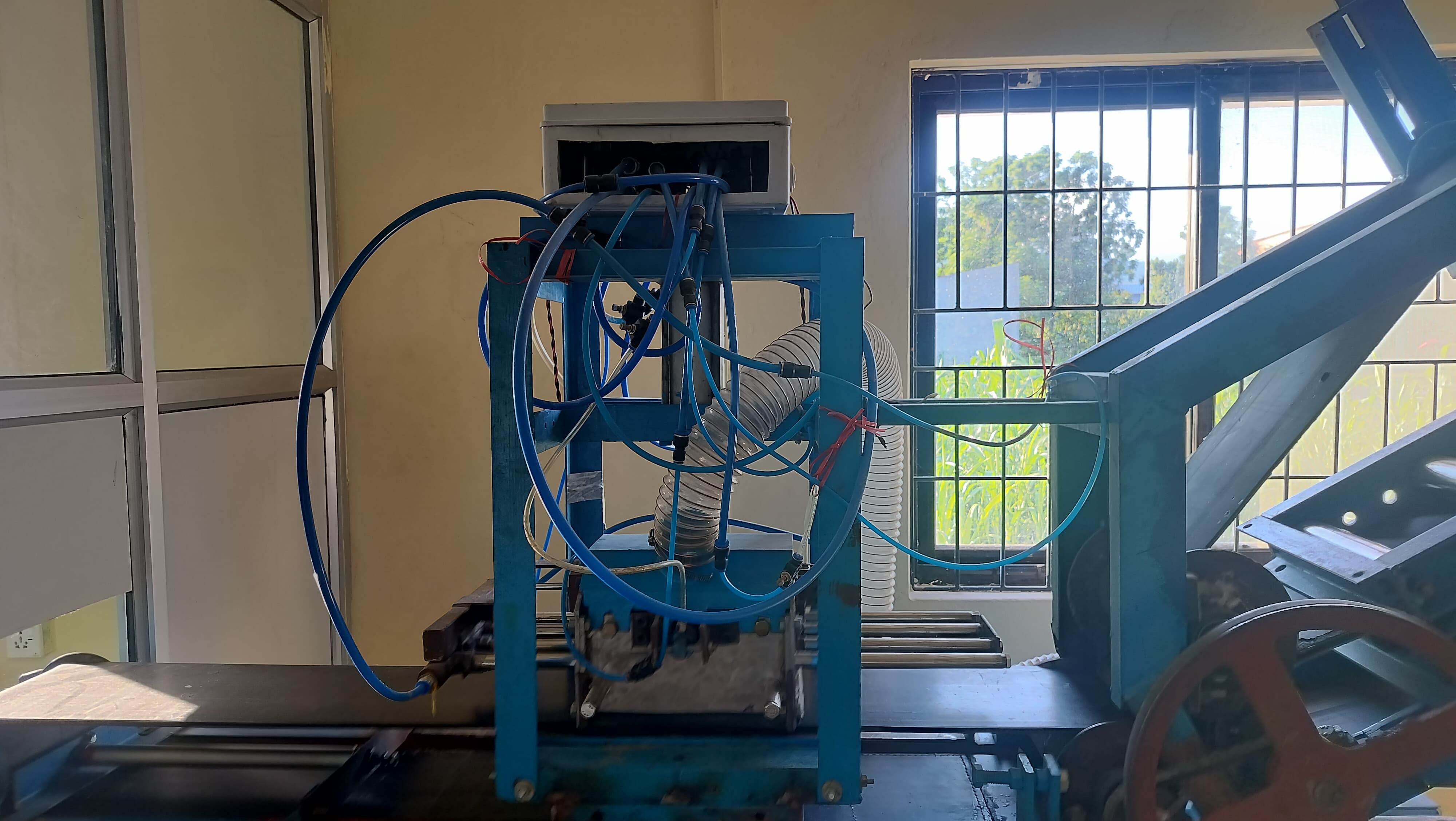

The machine is designed for efficient, scalable, and locally adaptable production. It integrates:

-

A horizontal screw conveyor system for uniform fiber feeding

-

A high-speed pulverizer for refining shredded banana fiber

-

A roller-based compression unit for consistent sheet formation

-

A pneumatic cutting system with suction for precise shaping

Core components include a 3-phase induction motor with VFD speed control, stainless-steel agitators to prevent clogging, and a centrifugal suction system to recycle excess fiber — ensuring minimal waste and optimal performance.

The system achieves a production capacity of 12 pads per minute, delivering reliable output while maintaining high absorbency and biodegradability standards.

Empowering Communities Through Local Production

Beyond engineering, this machine represents a model for decentralized manufacturing.

Its semi-automatic design allows small-scale units to operate in rural communities, creating opportunities for:

-

Women’s employment and entrepreneurship

-

Reduced dependency on imported products

-

Sustainable income generation

-

Agricultural waste valorization

This approach aligns with global goals for environmental sustainability and inclusive economic development.

Looking Ahead

While challenges such as seasonal raw material availability and initial setup costs exist, future enhancements — including increased automation and material optimization — will further strengthen the system’s impact.

This project demonstrates that engineering innovation can drive environmental responsibility and social empowerment simultaneously.