DUMBWAITER FOODLIFT

Product Specifications

Food Lift

We manufacture and install customized Food Lifts in Nepal, designed to simplify vertical transportation in hotels, restaurants, hospitals, residential buildings, and commercial spaces.

Our systems efficiently move food, groceries, and service items between floors — delivering meals to dining areas and safely returning used dishes to the kitchen. This improves service speed, reduces staff workload, minimizes accidents on stairs, and enhances hygiene.

Suitable for two-floor to multi-floor buildings, our food lifts are designed to fit both compact and large spaces, with flexible stop configurations based on your needs.

Reliable. Safe. Efficient. Built for modern service environments.

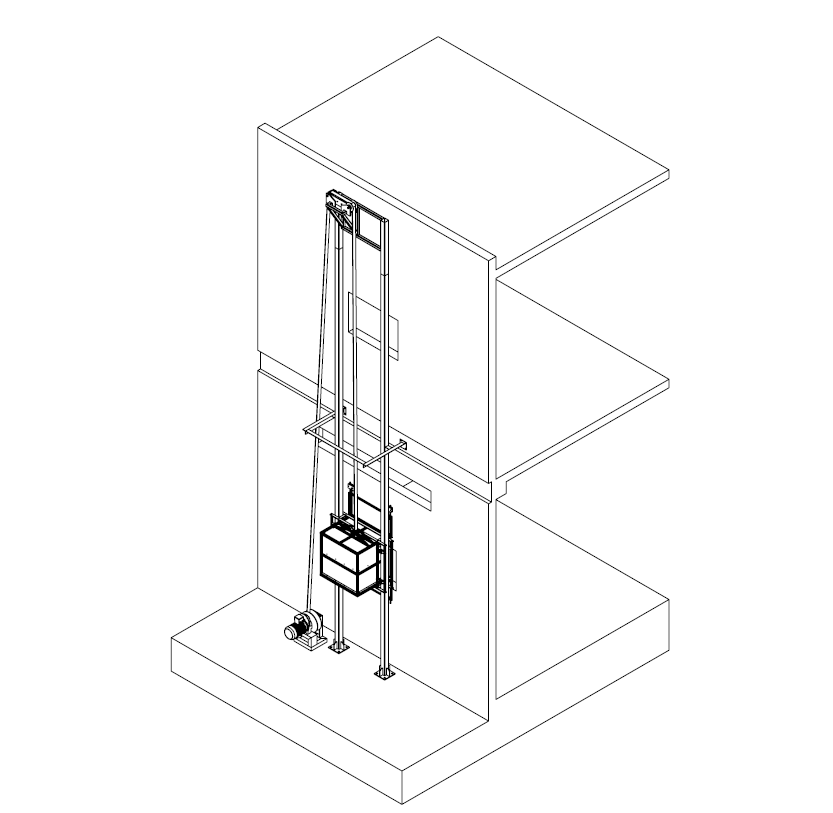

How It Works

The food lift operates through a motor-driven vertical system that transports trays, dishes, and supplies between designated floors. With secure cabin enclosures and controlled stops, it ensures smooth, safe, and hygienic movement of items without manual handling on staircases.

We have been successfully manufacturing and installing food lifts in various regions of Nepal.

Food Lift Specifications

| S.N | Feature | Specification |

|---|---|---|

| 1 | Number of Floors | 2 – 10 Floors |

| 2 | Installation Area | Min. 2ft × 2ft |

| 3 | Box Size | Customizable |

| 4 | Belt Type | Nylon / Steel |

| 5 | Door Type | Automatic / Manual |

| 6 | Winch | Single / 3 Phase |

| 7 | Guideway | Channel / Angle / Pipe |

| 8 | Input | Push Button |

| 9 | Material | Stainless Steel |

| 10 | Capacity | 20kg – 60kg |

Our Installed Clients

| S.N | Client | Location |

|---|---|---|

| 1 | X.O. Hospitality Group | Thamel |

| 2 | Carpe Diem Lounge | Thamel |

| 3 | Arabica Coffee | TIA |

| 4 | Purbeli Multi Cuisine | TIA |

| 5 | DAV Sushil Kedia | Lalitpur |

| 6 | Hotel Sherpali | Boudha |

| 7 | Hotel Sarowar | Pokhara |

| 8 | Traditional Comfort Hotel | Kathmandu |