Plastic Recycling Machine

Custom Mechanism Design

Plastic usage has become commonplace in almost every field of daily life. And consequently, plastic waste is also increasing rapidly. These wastes are not biodegradable and pollutes the environment around us. Thus a proper management of such waste has become a serious issue today. To help in managing the plastic waste, G.R.I.T. Engineering has designed and manufactured various machines and commercially started the plastic recycling process in the Kathmandu valley. These machines pelletize plastic wastes containing HDPE (High-Density Polyethylene) and this can be used to make HDPE water pipes, tanks, containers, etc. The overall process consists of washing, cutting, drying, mixing, extruding and pelletizing into fixed-sized pellets. Different machines used in the recycling process and their functions are described below:

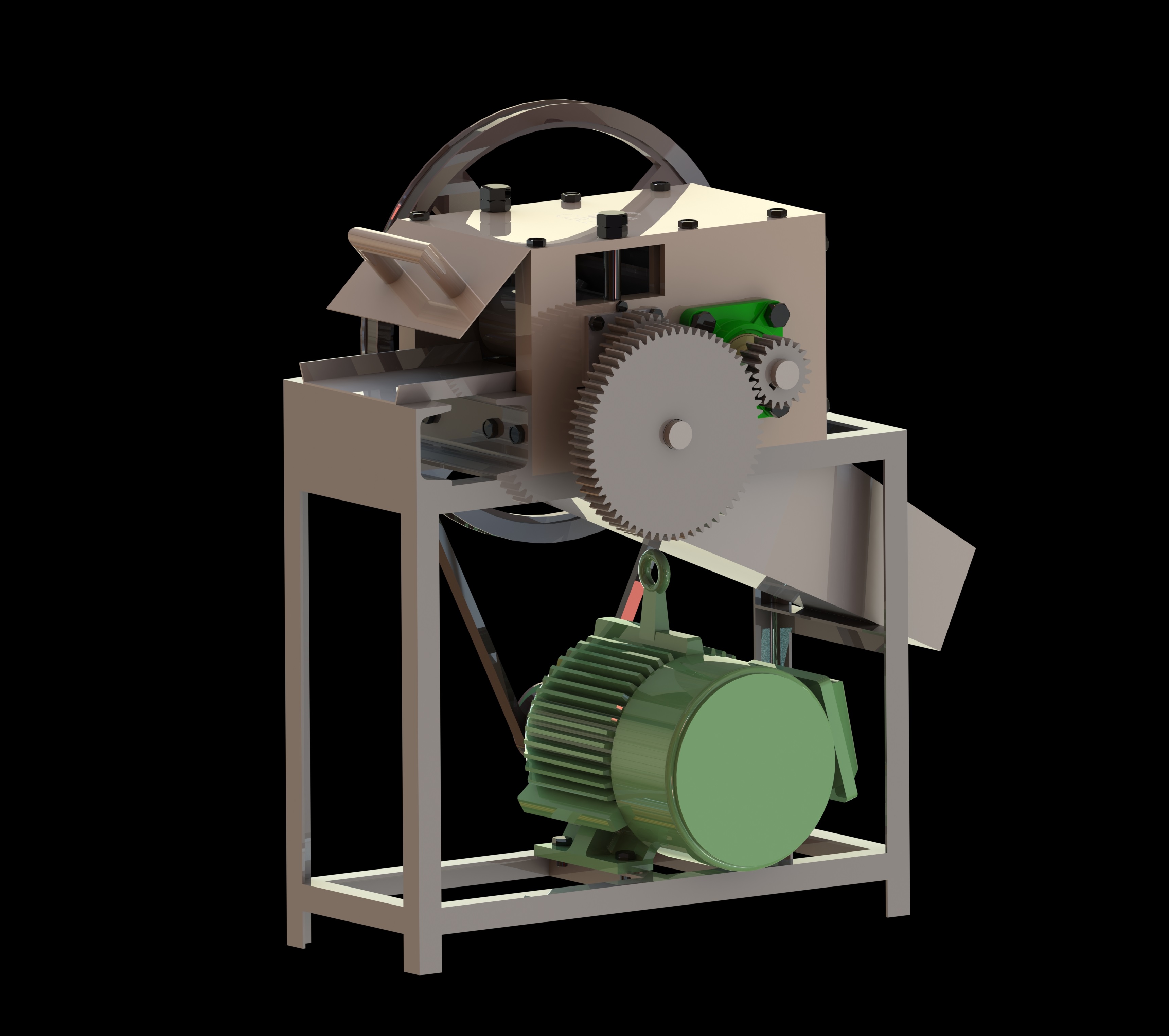

1. Granulator

After washing the plastic waste, it is transferred to Granulator. A plastic granulator, or sometimes referred to as crusher, has the unique ability to quickly and efficiently cut a stream of plastic scrap into small uniform pieces for recycling. It consists of four outer blades and four inner blades (two on each side). A 15hp, 3-phase motor rotates the inner blade with reduced speed through a set of 6-inch and 16-inch (2 groove, C-type) pulley. Plastic pieces are collected and send to the washing tank for further washing and then to dryer for drying.

| S.N. | Parts Name | Description | Quantity |

|---|---|---|---|

| 1 | Cylindrical Roller Bearing | ID: 70mm | 2 |

| 2 | Electric Motor | 20hp, 3 phase | 1 |

| 3 | Large pulley | 16 inch, 2 groove pulley (C) | 1 |

| 4 | Small pulley | 6 inch, 2 groove pulley (C) | 1 |

| 5 | Working volume | 552*358*360 mm3 | |

| 6 | Total Weight | 400 to 500 kg | |

| 7 | Capacity | 10-20 kg per lot | |

2. Dryer

Its main function is to dry the wet plastics pieces by centrifugal force. Wet plastic has been poured into the rotating cylindrical drum (net), and by centrifugal action, the wet plastic will be dried. It can dry about 8 to 15 kg of plastics in one lot. A 5hp, 3-phase motor rotates the cylinder through a set of 12-inch and 6-inch (2 groove, B-type) pulley. Further cutting is necessary for the ease of the extrusion process. Therefore mixture (for hard plastic) or agglomerator (for soft plastic) has been used for this purpose.

| S.N. | Parts Name | Description | Quantity |

|---|---|---|---|

| 1 | Conical Bearing | ID: 65mm | 1 |

| ID: 70mm | 1 | ||

| 2 | Electric Motor | 5hp, 3 phase | 1 |

| 3 | Large pulley | 12 inch, 2 groove pulley (B) | 1 |

| 4 | Small pulley | 6 inch, 2 groove pulley (B) | 1 |

| 5 | Working volume | ID: 696mm, Height: 377mm | |

| 6 | Total Weight | 200 to 300 kg | |

| 7 | Capacity | 8-15 kg of plastics per lot | |

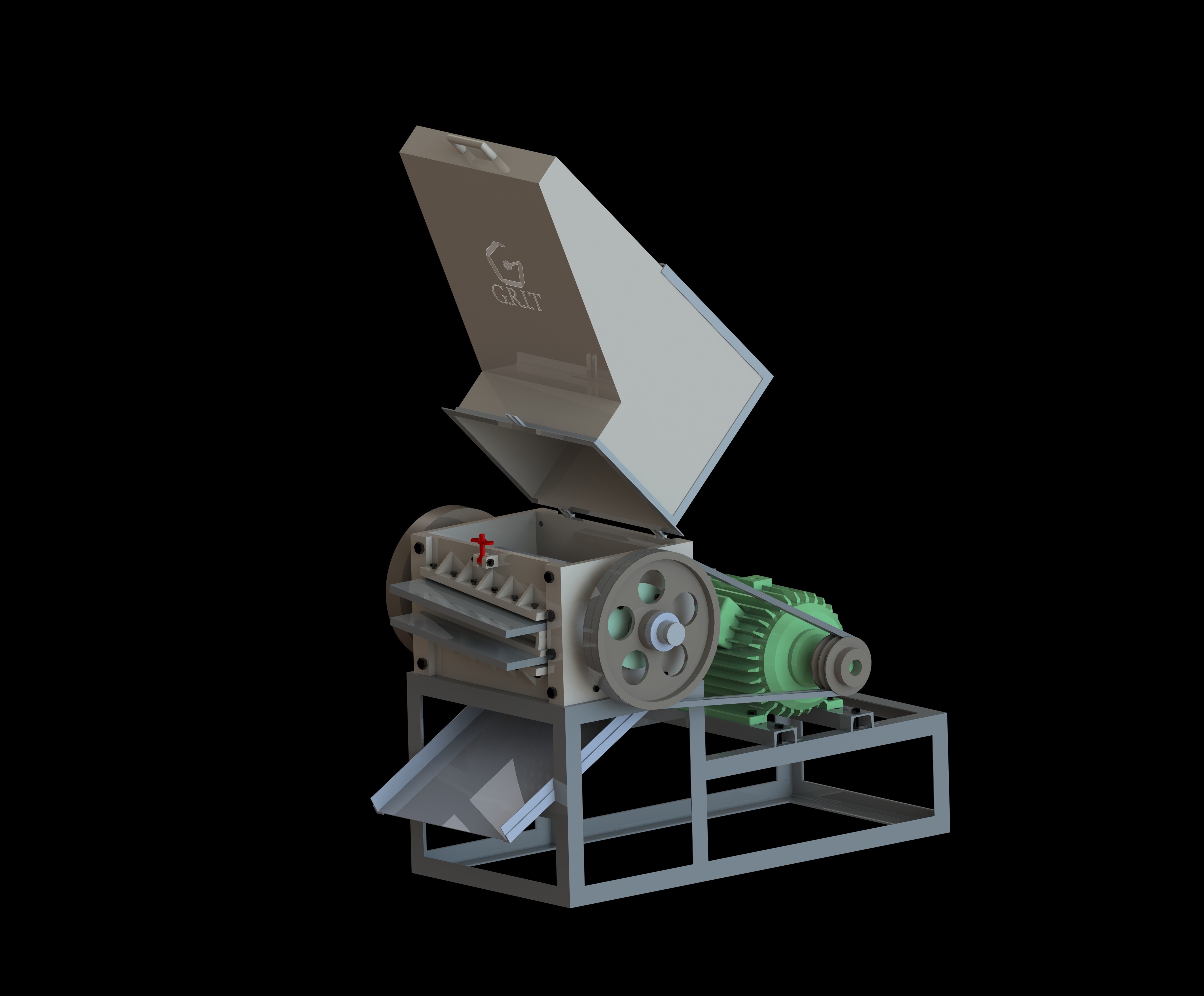

3. Agglomerator

Its main feature is crushing, mixing and heating (due to friction) the plastics in one step. It thus helps the extrusion process by making the homogenous mixture of various plastic wastes. It consists of a cylindrical container in which four high speed inner rotating blades and four outer fixed blades cut the plastics by shearing action. It's capacity ranges from 15-30 kg per lot. Mostly agglomerator is used for cutting soft plastics like LDPE (Low-Density Polyethylene). A set of 12-inches and 6-inches (3 groove pulley), coupled with a 40hp 3-phase motor has been used for agglomerator.

| S.N. | Parts Name | Description | Quantity |

|---|---|---|---|

| 1 | Conical Bearing | ID: 85mm | 1 |

| ID: 90mm | 1 | ||

| 2 | Electric Motor | 40hp, 3 phase | 1 |

| 3 | Large pulley | 12 inch, 3 groove pulley (C) | 1 |

| 4 | Small pulley | 6 inch, 3 groove pulley (C) | 1 |

| 5 | Working volume | ID: 568mm, Height: 420mm | |

| 6 | Total Weight | 700 to 800 kg | |

| 7 | Capacity | 15-30 kg per lot | |

4. Mixture

Hard plastic waste like HDPE, HM bottles require robust blades for cutting, so mixture is one of the widely used machine for this cutting process. Its function is not only to cut but also to make a homogeneous mixture of plastic wastes. It's capacity ranges from 15-30 kg per lot. It consists of a set of 12-inch and 6-inch pulley (3 groove, C-type) and a 20hp electric motor.

| S.N. | Parts Name | Description | Quantity |

|---|---|---|---|

| 1 | Conical Bearing | ID: 55mm | 1 |

| ID: 70mm | 1 | ||

| 2 | Electric Motor | 20hp, 3 phase | 1 |

| 3 | Large pulley | 12 inch, 3 groove pulley (C) | 1 |

| 4 | Small pulley | 6 inch, 3 groove pulley (C) | 1 |

| 5 | Working volume | ID: 628mm, Height: 756mm | |

| 6 | Total Weight | 700 to 800 kg | |

| 7 | Capacity | 15-30 kg per lot | |

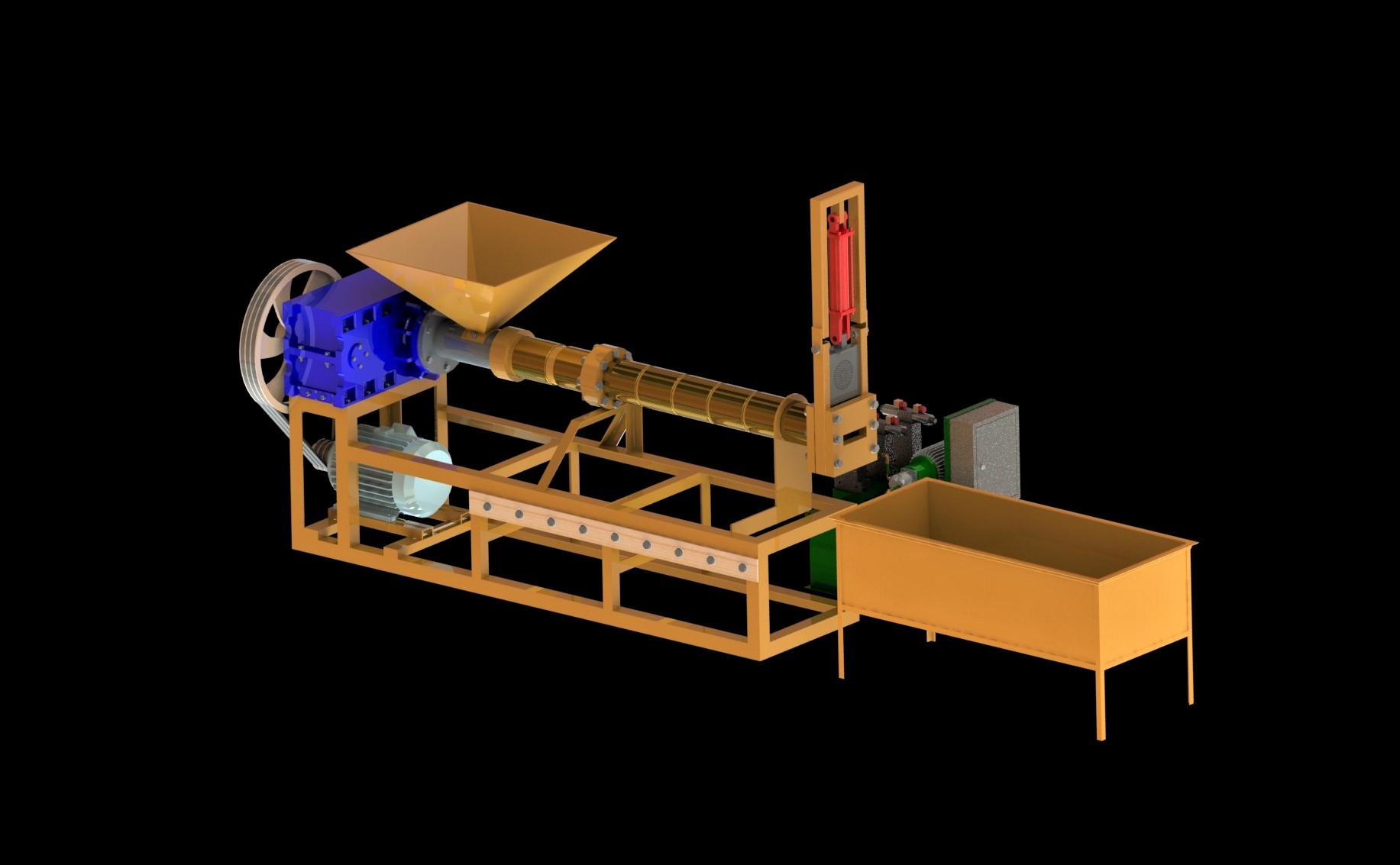

5. Extruder

Plastic extrusion is a process in which raw plastic is melted (partially) and formed into a continuous process. This process starts by feeding plastic material (after mixture or agglomerator) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling through water.

6. Pelletizer Machine

This machine consists of a set of rollers that sends continuous plastic to the rotating blades, which cut the continuous plastics to fixed-sized (6-10mm) pellets/granules. These pellets can directly put into the production line for plastics injection machines.